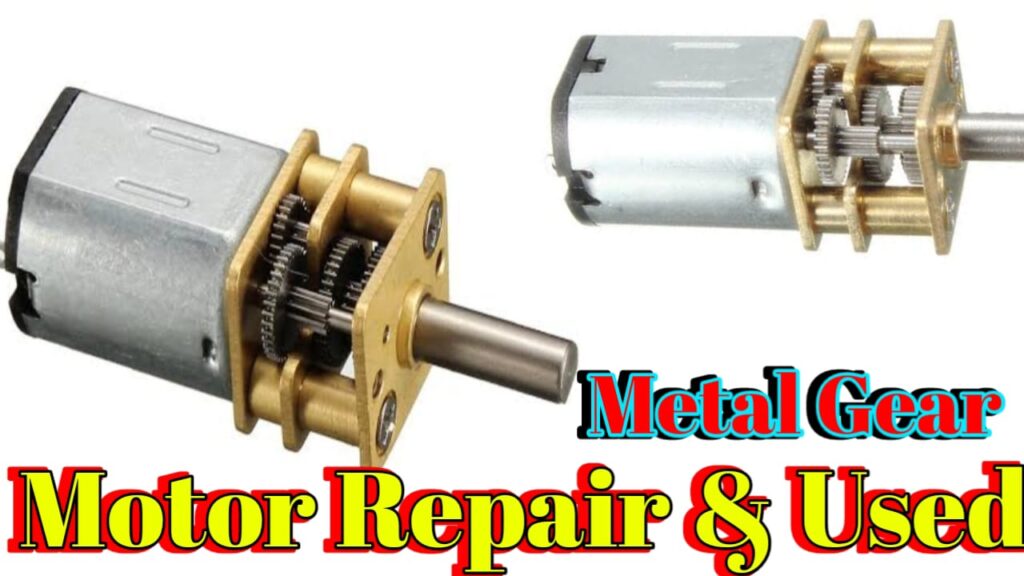

Metal Gear DC Motors serve as essential components in various electronic devices, including school projects. Understanding how to repair these motors can be a valuable skill, especially for students engaged in hands-on projects. In this article, we’ll explore the ins and outs of Metal Gear DC motor repair and how it can be seamlessly incorporated into school projects.

Introduction

Metal Gear DC Motors are ubiquitous in the realm of electronics, powering an array of devices from small gadgets to school project prototypes. However, these motors are not immune to wear and tear. The need for repair arises, presenting an excellent opportunity for students to learn and apply practical skills in their projects.

Understanding Metal Gear DC Motors

Before diving into repair procedures, let’s comprehend the basics of Metal Gear DC Motors. These motors, known for their durability and efficiency, consist of intricate components susceptible to damage over time. Identifying common issues is crucial to effective repair.

Tools and Materials Needed

To embark on a successful repair journey, gather the necessary tools and materials. A comprehensive list ensures a smooth process, from disassembly to reassembly. From screwdrivers to replacement gears, having the right equipment is paramount.

Step-by-Step Guide to Metal Gear DC Motor Repair

Disassembly of the Motor

Begin by carefully disassembling the motor, taking note of each component’s placement. A systematic approach prevents confusion during reassembly.

Identification of Damaged Components

Thoroughly inspect each part for signs of damage. From worn-out gears to faulty wiring, pinpointing issues is the key to effective repair.

Sourcing Replacement Parts

Once identified, source quality replacement parts. Online platforms and local electronic stores are excellent resources for obtaining the required components.

Step-by-Step Repair Process

Follow a detailed repair guide, addressing each issue systematically. From soldering connections to replacing gears, take your time to ensure precision.

Tips for Effective Repair

Best Practices for Successful Repairs

Adopt best practices to enhance the longevity of the repaired motor. Proper lubrication and careful handling contribute to the motor’s optimal performance.

Common Pitfalls to Avoid During the Repair

Beware of common mistakes, such as mismatched gears or improper wiring. Understanding potential pitfalls ensures a smoother repair experience.

Benefits of DIY Metal Gear DC Motor Repair

Cost-Effectiveness

DIY repair not only saves money but also instills a sense of accomplishment. Students can allocate saved funds to other aspects of their projects.

Skill Development for School Projects

Learning the intricacies of motor repair enhances students’ technical skills, providing a practical foundation for future projects and endeavors.

Incorporating the Repair into School Projects

Integrating the repaired motor into different projects adds a unique dimension to school assignments. It fosters creativity and demonstrates the practical application of theoretical knowledge.

Safety Precautions

Importance of Safety During the Repair Process

Emphasize safety when working with electrical components. Use insulated tools, wear protective gear, and work in a well-ventilated area.

Safety Tips for Handling Electrical Components

Provide specific tips, such as disconnecting power sources and avoiding contact with live wires. Safety should be a top priority throughout the repair process.

Real-Life School Project Examples

Highlighting successful school projects using repaired motors serves as inspiration. These examples showcase the versatility of repaired motors in various applications.

Importance of Sustainability

Encourage sustainable practices by repairing and repurposing electronic components. Reduce electronic waste and contribute to a more environmentally friendly approach to technology.

Challenges and Solutions in Metal Gear DC Motor Repair

Addressing Common Challenges Faced During Repairs

From difficulty in sourcing parts to intricate repairs, address challenges readers might encounter. Providing solutions adds practical value to the article.

Providing Effective Solutions

Offer step-by-step solutions to common issues. Whether it’s fixing a misalignment or soldering a connection, clarity is essential for successful repairs.

Future Applications of Metal Gear DC Motors

As technology evolves, discuss emerging applications of Metal Gear DC Motors. This section sparks curiosity about the potential future uses of these motors in upcoming school projects.

Engaging Students in DIY Repairs

Encourage students to embrace hands-on learning. DIY repairs not only enhance technical skills but also foster a proactive and problem-solving mindset.

Success Stories

Share success stories of individuals who have undertaken motor repairs for their school projects. These anecdotes inspire readers to overcome challenges and embark on their repair journey.

Conclusion

In conclusion, learning how to repair Metal Gear DC Motors presents an invaluable opportunity for students engaged in school projects. Beyond the immediate benefits of cost savings, it fosters skill development, encourages creativity, and contributes to a sustainable approach to technology.

Thank you very much visiting for websitehttps://creativitytopper.com

- How To Make DIY Mini bus Project From Cardboard at home. - May 8, 2024

- How To Make Humidifier Spray Module / Mist Maker Project . - April 27, 2024

- How To Make a New Model Subwoofer Box Project by Cardboard - April 15, 2024